Frequently Asked Questions

How does a cardboard baler machine work?

Cardboard balers are very easy to operate. Cardboard waste is loaded into the chamber, and once it is full, the machine is activated. A metal ram pushes down onto the cardboard at great force, crushing the waste into a compact bale. Once baled, the waste can be tied off with banding and removed from the baler ready for collection.

What materials can go in cardboard balers?

This depends on the type of recycling baler you have. Some machinery can handle cardboard as well as other recyclables such as paper or plastic, while others are only able to process cardboard waste.

Does my business need a cardboard baler?

Many businesses decide they need a cardboard baler machine once their recycling requirements increase to a point where they can’t manage it manually. When staff are having to process a lot of cardboard waste by hand, it can hinder other areas of the business, and cardboard balers can help with this.

How much does it cost to buy an industrial cardboard baler?

The cost of a cardboard baler will depend on the type and size of the machine. Industrial cardboard balers are generally top of the line models which have a higher price tag, although there are smaller models which are more budget friendly.

What size cardboard baler is right for me?

It is important to understand what size machine you need before you start looking for a cardboard baler for sale. Think about the filling opening and how much space you need to get your cardboard waste into the chamber. Consider the bale size required and how much space you have on premise for storing these before collection.

Do cardboard baler machines require maintenance?

As with all machinery, cardboard balers require regular servicing to keep them running smoothly. Once you buy a cardboard baler, you should ensure you have a servicing strategy in place, as failing to look after the machine can result in downtime and further issues.

Speak to One of Our Machinery Experts

Get in touch to request a call back from one of our Machinery Experts about your

Waste and Recycling needs.

Click or press on the button to open our enquiry form and we'll come back to you

ASAP with answers, options, prices and services.

Book a Free Site Survey

Schedule a free, no-obligation site survey and find out how to…

- Get guidance on the most effective way to recycle waste materials

- Reduce your waste disposal costs

- Reduce the time staff spend on processing/handling waste

- Stay compliant & environmentally friendly

- Maintain an excellent level of health & safety

- Find out when it’s time to replace ageing equipment

Knowledge Centre

Our recycling machine specialists are sharing everything you need to know

about waste and recycling machinery. Explore our knowledge centre.

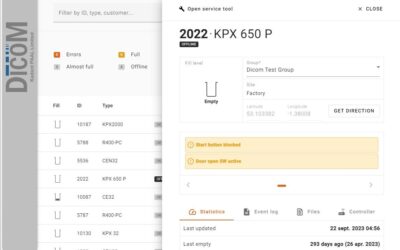

Kadant PAAL Ltd Launch Dicom Connect

We are now ready, after comprehensive in place testing, to unveil and launch our exclusive Dicom Connect client platform to all our customers new and old (if their existing Dicom equipment is fitted with RMS and they would like to upgrade the equipment as an optional...

Kadant PAAL Ltd at RWM 2024

Kadant PAAL Ltd are exhibiting again this year at RWM 2024. Our Sales Team, encompassing the Dicom Product range and the PAAL Product range will be here to meet you. It will be great to chat with our customers new and old and discuss what’s happening for us all....

Travelling Taverna lunch Treat for all staff at Kadant PAAL Ltd.

All departments got together, Sales, Service, Technical, Production and Finance to enjoy this luscious lunch and we were blessed with a sunny day! Everyone taking a moment and the rare opportunity when all of our teams could be together. Sunshine, delicious food and a...