Recycling Balers

Vertical Balers

The DICOM range of vertical balers offers a versatile range of efficient, space-saving solutions that are perfect for businesses looking to optimize their waste management processes and reduce disposal costs.

Find Out More

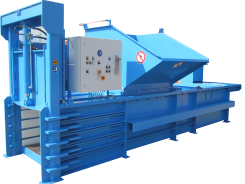

Horizontal Balers

Explore our range of high-performance waste management solutions, designed to handle large volumes of waste and maximise recycling revenue for businesses

of all sizes.

Find Out More

Our Recycling Balers

Recycling balers are one of the most common types of waste machinery and are used by all kinds of businesses from start-ups to international organisations. With consumer demand for environmentally friendly brands growing, it is essential that you have a stable and comprehensive waste management strategy in place. Recycling machinery balers are a critical part of any waste strategy, and can be vital in helping your business keep on top of its waste disposal. No matter the size of the business, recycling balers can bring many benefits including reduced overheads, increased profits, and better-organised workspaces.

There are various types of recycling balers for sale, and these machines work by using a compaction ram with a very high force in order to compact waste materials. Many recyclable materials such as paper, cardboard, and plastics can be used in recycling balers and therefore removed from landfill waste streams. Recycling machinery balers work to compact these waste materials down into solid blocks which are known as bales.

Bales produced from recycling balers can sometimes be collected for free by waste disposal companies, and in some cases it is possible to use these bales to create another revenue stream. Using a recycling baler can help keep skips and bins on premises clear and free for landfill waste only, while also encouraging recycling among your organisation. This kind of recycling machinery is particularly popular among restaurants, retail stores, supermarkets, offices, and warehouses which produce a lot of cardboard, paper, and plastic waste.

Benefits of Recycling Balers

Discover the many benefits of choosing a recycling baler for your business's waste management needs below.

Recycling balers compress waste materials into dense bales, reducing waste volume and the need for frequent disposal

With their compact design, recycling balers save valuable space in workplaces and storage areas

Recycling balers maximize recycling revenue by creating high-quality bales that can be sold to recycling companies

Recycling balers promote sustainability by reducing waste and encouraging recycling

By reducing waste volume and improving waste storage, recycling balers can improve workplace safety by reducing the risk of accidents and fire hazards

Recycling balers streamline waste management processes and improve efficiency by reducing labour costs and time spent on waste disposal

Recycling balers help reduce the environmental impact of waste disposal by minimizing the amount of waste sent to landfills

Recycling balers help businesses meet waste management regulations and avoid fines for non-compliance

Frequently Asked Questions

How do recycling balers work?

Recycling machinery balers work by using an extreme force on waste material, compressing the loose items into a tight, solid bale. Recyclables are placed inside the opening of the machine, and then a press plate is used to compact the materials down and compress them together. The chamber has retainers which work to prevent the materials from expanding and ensure the bale is as compact as possible.

What materials can go in a recycling baler?

There are various types of recyclables that can go into a recycling baler, including plastic, cardboard, aluminium, and paper. Some recycling machinery balers are specialised for a specific type of material, such as cardboard balers or plastic balers.

What types of recycling balers are available?

When looking at recycling balers for sale you are likely to come across both vertical balers and horizontal balers. They each work in a similar way but with slightly different operating procedures, e.g. where the materials are put in and where the bales are formed.

Are recycling machinery balers noisy?

Some recycling machinery can be very loud and cause disruption on premises; however, the majority of recycling balers are relatively quiet. They can be used within a working environment without causing any negative impact on workers.

How much waste can a recycling baler handle?

The volume of material able to go into a recycling baler will depend on the size of the machine you have. A small model can usually produce bales around 30kg, while a large machine can handle much higher volumes.

Do recycling balers require maintenance and servicing?

Properly looking after your recycling baler can help prolong its life and ensure it is working efficiently. Like all machinery, recycling balers benefit from a regular service and continued maintenance.

How We Can Help You

Let us help you optimise your waste management processes with efficient, cost-effective, and reliable solutions, backed by decades of industry experience, expert advice, and exceptional customer support.

Become Waste Efficient

Get guidance on the most effective, efficient way to recycle waste materials

Save Your Staff's Time

Reduce the time staff spend on processing/handling waste

Reduce Your Costs

Reduce your waste disposal costs

Reduce Your Footprint

Stay compliant & environmentally friendly

Stay Safe

Maintain an excellent level of

health & safety

Plan Ahead

Find out when it’s time to replace

ageing equipment

Our Services

and keep it running smoothly for many years. Explore our services below.

MasterCare

Dicom Connect

Service and Maintenance

Keep your equipment in top condition with regular servicing and expert maintenance.

Spare Parts

of recycling equipment.

Speak to One of Our Machinery Experts

Get in touch to request a call back from one of our Machinery Experts about your

Waste and Recycling needs.

Click or press on the button to open our enquiry form and we'll come back to you

ASAP with answers, options, prices and services.

Book a Free Site Survey

Schedule a free, no-obligation site survey and find out how to…

- Get guidance on the most effective way to recycle waste materials

- Reduce your waste disposal costs

- Reduce the time staff spend on processing/handling waste

- Stay compliant & environmentally friendly

- Maintain an excellent level of health & safety

- Find out when it’s time to replace ageing equipment

Knowledge Centre

Our recycling machine specialists are sharing everything you need to know

about waste and recycling machinery. Explore our knowledge centre.

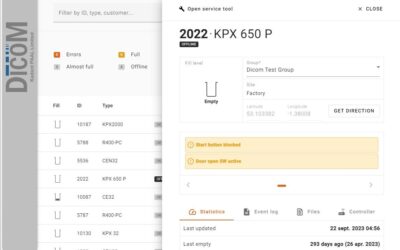

Kadant PAAL Ltd Launch Dicom Connect

We are now ready, after comprehensive in place testing, to unveil and launch our exclusive Dicom Connect client platform to all our customers new and old (if their existing Dicom equipment is fitted with RMS and they would like to upgrade the equipment as an optional...

Kadant PAAL Ltd at RWM 2024

Kadant PAAL Ltd are exhibiting again this year at RWM 2024. Our Sales Team, encompassing the Dicom Product range and the PAAL Product range will be here to meet you. It will be great to chat with our customers new and old and discuss what’s happening for us all....

Travelling Taverna lunch Treat for all staff at Kadant PAAL Ltd.

All departments got together, Sales, Service, Technical, Production and Finance to enjoy this luscious lunch and we were blessed with a sunny day! Everyone taking a moment and the rare opportunity when all of our teams could be together. Sunshine, delicious food and a...