Waste Compactors

Static Waste Compactors

The DICOM range of static waste compactors offers efficient and reliable waste management solutions for businesses of all sizes.

Find Out More

Portable Waste Compactors

The DICOM range of portable waste compactors offers efficient and reliable waste management solutions for businesses of all sizes.

Find Out More

Our Waste Compactors

Waste compactors are essential for proper waste management and can help businesses of all shapes and sizes to reduce space for waste on premises. They are a type of recycling equipment which is designed to store waste materials and recyclables in a compact and minimalist way, compared with standard bins and skips. Dicom compactors are some of the most reliable and trusted options available today and are used across a wide range of industries.

A waste compactor can reduce the amount of space used for storing waste by up to 90%, leaving more room on premises for other business activities. Dicom waste compactors are commonly used in offices, commercial businesses, schools, and industrial settings. Any premise which could benefit from reducing the amount of space used for storing waste should consider waste compactors as an effective solution.

These types of machines work by using hydraulic, pneumatic, and mechanical compression techniques to compact waste materials into a smaller space. Waste compactors can handle a wide range of refuse, whether that be bulky waste or organic waste. Our Dicom compactors are reliable, durable, and have been trusted by thousands of customers over the years. If you are looking for waste compactors for sale, contact our team today, or to find out more about waste compactors, read our FAQs below.

Benefits of Waste Compactors

Explore the multitude of benefits of choosing a waste compactor for your business’s

waste management needs below.

Waste compactors compress waste materials into dense blocks, reducing waste volume and the need for frequent disposal

With their compact design, waste compactors save valuable space in workplaces and storage areas

Waste compactors streamline waste management processes and improve efficiency by reducing labor costs and time spent on waste disposal

By reducing waste volume and improving waste storage, waste compactors can improve workplace safety by reducing the risk of accidents and fire hazards

Waste compactors promote sustainability by reducing waste and encouraging recycling, which helps to reduce the environmental impact of waste disposal

Waste compactors can help reduce odor and pest problems by containing waste materials and reducing the amount of waste exposed to the environment

Waste compactors come in a variety of sizes and configurations, offering customizable solutions to meet specific waste management needs

Waste compactors help businesses meet waste management regulations and avoid fines for non-compliance, ensuring compliance with environmental regulations

Frequently Asked Questions

How does a waste compactor work?

Dicom waste compactors are used to reduce the volume of rubbish, and they work in a similar way to rubbish trucks but on a smaller scale. Waste materials are placed inside the machine with a liner bag, when you operate the waste compactor a metal ram crushes the refuse into smaller volumes.

What are the benefits of Dicom compactors?

There are many benefits to investing in waste compactors for your business premises. One of the biggest advantages is the amount of space that can be saved by compacting waste down significantly. This also leads to cost savings as fewer waste collections will be required when your refuse is properly reduced.

Are there different types of waste compactors?

Yes, waste compactors come in various different types, including static compactors, portable compactors, vertical compactors and twin compactors.

How to choose the right waste compactor for sale?

With so many types of waste compactors, it can be confusing to know which is right for your operations. Start by analysing the volume of waste being produced, where a waste compactor would fit on your premises, and what kind of materials will you need to compact. Once you understand these aspects of your waste management, you will be better placed to identify the right waste compactor for you.

What is the difference between waste compactors and balers?

Both waste compactors and balers work to reduce the amount of space refuse takes up. Despite the similarities, these are slightly different machines with different capabilities. The main variation is that waste compactors can handle organic waste, while balers often can’t. Waste compactors are usually used for processing unsorted rubbish while balers are for recyclables.

Should I consider waste compactors for sale or for hire?

Waste compactors are available for both sale and rent, and the right option will depend on your unique requirements. If your business generates a large amount of waste on a regular basis, owning a waste compactor could be very worthwhile. However, if you produce small amounts of waste or have seasons where you have more refuse to move than others, renting a waste compactor could be the solution.

How We Can Help You

Let us help you optimise your waste management processes with efficient, cost-effective, and reliable solutions, backed by decades of industry experience, expert advice, and exceptional customer support.

Become Waste Efficient

Get guidance on the most effective, efficient way to recycle waste materials

Save Your Staff's Time

Reduce the time staff spend on processing/handling waste

Reduce Your Costs

Reduce your waste disposal costs

Reduce Your Footprint

Stay compliant & environmentally friendly

Stay Safe

Maintain an excellent level of

health & safety

Plan Ahead

Find out when it’s time to replace

ageing equipment

Our Services

and keep it running smoothly for many years. Explore our services below.

MasterCare

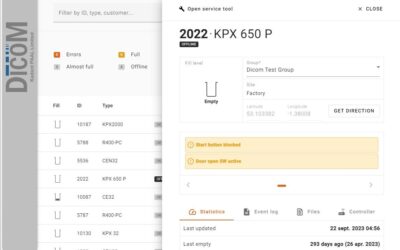

Dicom Connect

Service and Maintenance

Keep your equipment in top condition with regular servicing and expert maintenance.

Spare Parts

of recycling equipment.

Speak to One of Our Machinery Experts

Get in touch to request a call back from one of our Machinery Experts about your

Waste and Recycling needs.

Click or press on the button to open our enquiry form and we'll come back to you

ASAP with answers, options, prices and services.

Book a Free Site Survey

Schedule a free, no-obligation site survey and find out how to…

- Get guidance on the most effective way to recycle waste materials

- Reduce your waste disposal costs

- Reduce the time staff spend on processing/handling waste

- Stay compliant & environmentally friendly

- Maintain an excellent level of health & safety

- Find out when it’s time to replace ageing equipment

Knowledge Centre

Our recycling machine specialists are sharing everything you need to know

about waste and recycling machinery. Explore our knowledge centre.

Kadant PAAL Ltd Launch Dicom Connect

We are now ready, after comprehensive in place testing, to unveil and launch our exclusive Dicom Connect client platform to all our customers new and old (if their existing Dicom equipment is fitted with RMS and they would like to upgrade the equipment as an optional...

Kadant PAAL Ltd at RWM 2024

Kadant PAAL Ltd are exhibiting again this year at RWM 2024. Our Sales Team, encompassing the Dicom Product range and the PAAL Product range will be here to meet you. It will be great to chat with our customers new and old and discuss what’s happening for us all....

Travelling Taverna lunch Treat for all staff at Kadant PAAL Ltd.

All departments got together, Sales, Service, Technical, Production and Finance to enjoy this luscious lunch and we were blessed with a sunny day! Everyone taking a moment and the rare opportunity when all of our teams could be together. Sunshine, delicious food and a...