Vertical Balers

Vertical balers are a great option for small enterprises looking to improve their waste management strategy. These recycling machines are simple to use, cost-effective, and efficient for many small to medium sized businesses. Vertical baler machines are often considered an entry level type of equipment, compared with horizontal balers which are better suited to large premises and high volumes of waste.

Sometimes called downstroke balers, vertical baler machines use one compression ram to compact the waste material down into the bottom of the chamber. Due to the nature of vertical balers, they are versatile and often portable, making them ideal for small premises and multiple uses. Vertical balers are commonly used by retail stores, supermarkets, and small businesses that produce significant amounts of recyclable waste such as cardboard, plastic, or cans.

Bales produced from vertical balers can often be collected for free by waste management services or sold for a profit to recycling companies. Some businesses are able to use vertical baler machines as a method for creating a new revenue stream while also supporting sustainability initiatives. We are specialised vertical baler manufacturers and can help your business find the right machinery for your needs. Browse our frequently asked questions or get in touch with out expert team today.

Frequently Asked Questions

How do vertical balers work?

Vertical baler machines work to compress waste materials into a compacted bale using a high force. Loose recyclable materials are put into the baler, and a press plate then pushes the contents down into the base of the chamber. The materials are prevented from expanding by retainers in the chamber, creating a compact bale of recyclable material.

What materials can go in a vertical baler machine?

Cardboard, plastic, aluminium, and textiles can all be compacted using a vertical baler. Some balers are designed specifically for use with one type of material, while others have the ability to handle multiple types of waste.

What is the rate of compaction with a vertical baler?

Low density plastics and cardboard waste can typically see compaction ratios of 10:1, which is considered the standard rate.

How large are the bales produced from vertical balers?

This can depend on the type of vertical baler you are using, but some machines are able to produce small bales which are no heavier than 30kg. For large volumes of waste and large bales, such as mill sized bales, a horizontal baler might be a better solution.

Are vertical balers noisy?

It is a common concern among businesses that recycling machinery is going to be too loud for use in common workspaces. Vertical baler machines are typically very quiet and don’t pose any risk to operators.

What are the benefits of a vertical baler?

Vertical balers are easy and safe to use, extremely durable, and have low noise levels. They can help a business to save time, space, and money on waste disposal.

How to find vertical balers for sale?

There are many vertical balers for sale from various manufacturers. We are specialist vertical baler manufacturers and produce a range of recycling machinery to suit all requirements. For more information on vertical balers for sale, contact our team.

Speak to One of Our Machinery Experts

Get in touch to request a call back from one of our Machinery Experts about your

Waste and Recycling needs.

Click or press on the button to open our enquiry form and we'll come back to you

ASAP with answers, options, prices and services.

Book a Free Site Survey

Schedule a free, no-obligation site survey and find out how to…

- Get guidance on the most effective way to recycle waste materials

- Reduce your waste disposal costs

- Reduce the time staff spend on processing/handling waste

- Stay compliant & environmentally friendly

- Maintain an excellent level of health & safety

- Find out when it’s time to replace ageing equipment

Knowledge Centre

Our recycling machine specialists are sharing everything you need to know

about waste and recycling machinery. Explore our knowledge centre.

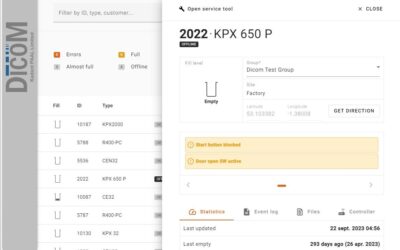

Kadant PAAL Ltd Launch Dicom Connect

We are now ready, after comprehensive in place testing, to unveil and launch our exclusive Dicom Connect client platform to all our customers new and old (if their existing Dicom equipment is fitted with RMS and they would like to upgrade the equipment as an optional...

Kadant PAAL Ltd at RWM 2024

Kadant PAAL Ltd are exhibiting again this year at RWM 2024. Our Sales Team, encompassing the Dicom Product range and the PAAL Product range will be here to meet you. It will be great to chat with our customers new and old and discuss what’s happening for us all....

Travelling Taverna lunch Treat for all staff at Kadant PAAL Ltd.

All departments got together, Sales, Service, Technical, Production and Finance to enjoy this luscious lunch and we were blessed with a sunny day! Everyone taking a moment and the rare opportunity when all of our teams could be together. Sunshine, delicious food and a...